MALE IN WHITE SHIRT:'The thrust when this vehicle takes off is about the equivalent of 12 A380 Airbuses taking off.' This is a pretty rough ride for the satellite, and that's what all the design and everything is about.

MALE IN WHITE SHIRT:'This is the bit where we all get that little bit of butterflies in the stomach.'

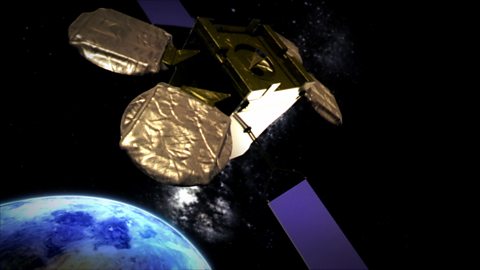

NARRATOR:'Telecommunication satellites orbit the Earth, allowing us to send television pictures and communicate over vast distances. They have to be able to operate in the harsh environment of deep space for a minimum of 15 years without fail. This requires some advanced engineering. However, the biggest challenge and most critical point'

NARRATOR:'is the extreme violence of the rocket launch. A satellite is built of thousands of electronic components. Every single one has to undergo a series of tests to ensure they won't fail and stop the satellite from working. Astrium's engineers lead the world in satellite design and manufacturing. Today, a frequency generator'

NARRATOR:'which helps the satellite communicate with Earth is going through the launch test.'

GARY STANCOMBE:My name's Gary Stancombe. I've worked in vibration test and mechanical test at Astrium for 15 years now. I'm just gonna do a little bit of taping down to tidy it up, and then we'll be ready.OK.

NARRATOR:'This test is to check that the component will survive the extreme physical impact of the satellite's launch.'

GARY STANCOMBE:What we're doing today is we're gonna subject this unit to a sequence of vibration tests to simulate the launch environment when the rocket lifts off and those eight minutes which will take it into space. It does get a fair old shake, so today we're gonna subject it to a 20 g vibration test, 20 times gravity.

GARY STANCOMBE:So anything in there will feel 20 times heavier.

NARRATOR:'Every electronic component is tested in this way. Sometimes to breaking point.'

GARY STANCOMBE:It is a hard test, yeah. It's a thorough test, so… It has to be, we have to ensure that everything is gonna still be working once the unit gets into space. We do see failures, but not too often.

NARRATOR:'It's not just the vibration of the launch that each component has to cope with. There are also massive shockwaves caused as explosive charges decouple at each stage of the rocket. From the solid boosters, the satellite housing and main engine through to the deployment of the satellite itself.'

GARY STANCOMBE:'These are quite substantial shockwaves so they need to be tested for.' OK, and that's the shock test.

NARRATOR:'Thanks to tests like this, the spacecraft can now survive the launch and start its life in space. 35,786km above us, satellites constantly operate, transmitting signals down to Earth. Making sure you can watch TV, go online, and use your mobile phone.'

Video summary

A satellite has to undergo extreme physical stresses as it is launched, during its flight and so it remains functional for 15 years.

We see a satellite launch and learn what these stresses are. Each component has to be fit for purpose, thereby they must survive the vibration of the launch, substantial shock waves and explosive charges.

We visit British satellite company, Astrium to witness two rigorous tests; a 20 G vibration test and a shock test. A mixture of graphics and footage lead us through this journey.

Teacher Notes

Could be used to demonstrate how testing should consider the demands that will be placed on a product.

The class could consider additional tests that would be needed if the satellite was to host astronauts or for a lunar lander.

These might include immersion testing to check that the astronauts living area is airtight and testing resistance to changes in temperature.

Students could then prepare a list of the tests that would be needed for a specified simple product, such as an item of cutlery or a chair.

This would involve producing list of the required properties and specifying a suitable test for each of them.

This clip will be relevant for teaching KS3 and KS4/GCSE Design and Technology, materials.

This topic appears in OCR, Edexcel, AQA, WJEC in England and Wales, CCEA in Northern Ireland and SQA National 4/5 and Higher in Scotland.

How satellites survive in space. video

A thermal architect explains how satellites are designed.

How smart materials are used in renewable energy solutions. video

This video looks at an organisation, Qinetiq, develops stealth materials to help military aircraft avoid detection on enemy radars.

Engineering apprenticeships. video

Two engineering apprentices describe their work on a nuclear submarine at BAE Systems in Barrow-in-Furness and at a Rolls Royce factory in Derby.