How to do risk assessment

Learn how to plan for health, safety and security risks and hazards, and minimise the chances of harm or damage

What is risk assessment?

Risk assessment is a simple way to plan what you're going to do to minimise the chances of anybody getting hurt or causing damage to property or equipment. It's how to identify sensible measures to control the risks in your workplace.

Consider health, safety and security from the start. How can it be managed responsibly? Be clear and specific about what's going to be assessed. Concentrate on real risks – those that are most likely and which will cause the most harm. You should be competent to complete risk assessments and know what could go wrong and how to control it. If you don’t know, ask someone who does.

This guide will help you understand the process so you can assess risks accurately anywhere you work, whatever you're doing, whether it's for location shoots, breaking news, large music events, in engineering workshops or even just around the office.

How do i identify hazards

Know what you're planning to do – activities, locations, people, equipment, processes, substances and conditions. Think through what you're going to do in small chunks, and consider those things with a fair chance of happening. Click through the images to learn more.

What are hazards?

What could go wrong? What are the hazards? These are the things that might cause harm. This includes physical injury, psychological injury, health hazards or personal security threats.

What are you planning to do?

Know what activities you’re planning to do, what could actually happen and what could go wrong. Consider only those hazards which have a fair chance of happening and could also cause harm or damage.

Where are you working?

Think of where you are, what locations are you in and how being there might cause harm or cause things to go wrong.

Who is involved?

Is everybody competent and knowledgeable about what they're doing? Are there any special requirements? Are there children, pregnant women, those with disabilities? Are you using contractors?

What equipment is being used?

Think of the equipment being used. Where did you get it from? Is it well maintained and fit for its intended purpose? Are people trained to use it?

What are the weather conditions?

Think about the weather conditions and whether that will have an impact.

What is the type of harm?

Think about the weather conditions and whether that will have an impact.

What's the worst case?

Think worst case - consider emergency situations and contingency plans. If things go wrong, could these present additional hazards?

Who might be harmed and how?

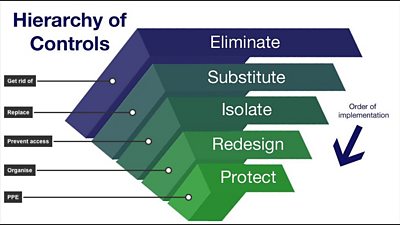

How do I identify controls?

Get rid of

Redesign the job or substitute a substance so that the hazard is removed or eliminated. For example, avoid working at height where you can.

Replace

Replace the material or process with a less hazardous one. For example, use a small mobile working platform to access work at height instead of stepladders. Take care to ensure the alternative is safer than the original.

Prevent access

Use work equipment or other measures such as engineering controls to prevent falls where you can’t avoid working at height. Install or use additional machinery such as local exhaust ventilation to control risks from dust or fumes. Separate the hazard from operators through methods such as enclosing or guarding dangerous items of machinery/equipment. Give priority to measures which protect collectively over individual measures.

Organise

Identify and implement the procedures you need to work safely. For example, by reducing the time workers are exposed to hazards (eg by job rotation), prohibiting use of mobile phones in hazardous areas, increasing safety signage and performing risk assessments.

PPE

Personal protective equipment (PPE) must only be used after all of the previous measures have been tried and found to be ineffective in controlling risks to a reasonably practicable level. For example, where you can’t eliminate the risk of a fall, use work equipment or other measures to minimise the distance and consequences of a fall. If chosen, PPE should be selected and fitted by the person who uses it. Workers must be trained in the function and limitation of each item of PPE.

What should i do with my findings

Record, communicate and implement

Putting it into practice and making it happen

The more complex the task or activity, the greater the potential severity and the more detail will be needed. Start your record as early as you can and keep adding to it as things come up and are decided. Share your findings and tell people what can go wrong and how it’s being managed. Do what you need to do to manage the risk and implement the controls.

Collect together all of your information to record your findings in a way that you can access later if necessary. Consider your audience and your use of language. Be clear, concise, specific and detailed, and avoid generic, vague comments. Any record produced should be simple and focused on controls. 91�ȱ� risk assessments are recorded in a tool called myRisks and signed off by a senior manager. If something did go wrong, the risk assessment may be reviewed by the Health and Safety Executive (HSE) and discussed in court.

Communicate: Communicate the controls and precautions

Make sure the details of control measures and precautions are shared with those who need to know, by the most effective way to get the message across. Use briefings to remind and reinforce key safety measures. Include safety information on call sheets, emails, noticeboards, and talk about safety in meetings. You could distribute the risk assessment and ask people to read it and act on it.

Implement the controls

Make sure control measures are put in place and carried out. Assign the task or control measure to someone in particular, and make sure they understand its importance. Check that controls are in place by monitoring and seeking assurances, or by obtaining documentary evidence of compliance.

What if things change?

When

When should you review? You should review your risk assessment if situations change from your original plans, or things are different than you predicted, to check it's still accurate.

Why

Why should you review? If there are significant changes you may need to stop the activity to revise the risk assessment and introduce any new controls before continuing.

How

How should you record changes? Once a decision has been made you must record, inform everyone and implement the changes. Use email, make notes, record or film on camera, or brief the team.

Summary

The risk assessment process is simple.

You should:

- identify what could go wrong

- identify who might be affected and how they might be harmed

- identify controls that are needed to stop it going wrong

- show that any remaining risk after all reasonable controls are in place is low enough to be acceptable

- record all of your findings and keep it

- tell everyone what they need to know and do

- make sure it all gets done

- ensure that if anything changes, you check you’ve got the right things in place. If not, stop the activity and review what's needed

You're not on your own – help is always available.

Where next?

91�ȱ� risk assessment guidance

91�ȱ� risk assessment guidance 91�ȱ� risk assessment useful tips

91�ȱ� risk assessment useful tips Contact your 91�ȱ� safety adviser

Contact your 91�ȱ� safety adviser 91�ȱ� Safety homepage

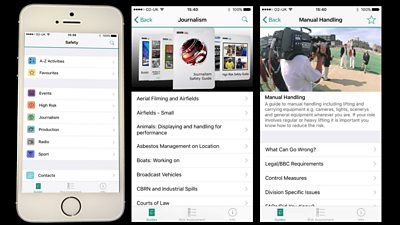

91�ȱ� Safety homepage 91�ȱ� Safety app

91�ȱ� Safety app 91�ȱ� Academy safety training courses (for staff only)

91�ȱ� Academy safety training courses (for staff only)